The elevator buffer is an important elevator part of the elevator system. Usually we install it in the bottom pit of the car and the counterweight shaft. It functions like a soft mattress, providing a safe and reliable lifting process for elevators. According to different working principles and design characteristics, elevator buffers can be divided into several main types.

Elevator buffers types mainly include energy-storage buffers and energy-consuming buffers. Polyurethane and spring buffers are energy-storage buffers, and hydraulic buffers are energy-consuming buffers.

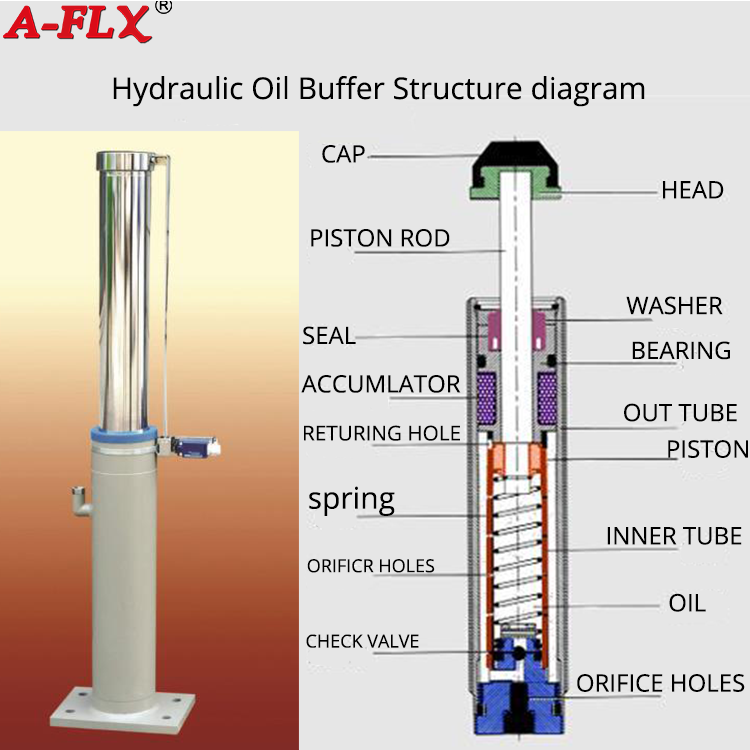

1.Hydraulic Oil Buffer: This type utilizes hydraulic damping to cushion and decelerate the elevator car or counterweight during inertial gliding until it comes to a stop. When the elevator car or counterweight impacts the buffer, the hydraulic oil buffer slows down the elevator by means of fluid flow, absorbing or dissipating the elevator’s energy. Hydraulic oil buffers are suitable for any speed, with elevators traveling at speeds greater than 1 meter typically using hydraulic buffers. They typically consist of hydraulic cylinders, valves, and fluids.

What is the buffer oil in the hydraulic buffer?

Elevator buffer oil is the hydraulic medium used in the hydraulic system using liquid pressure energy. It plays the role of energy transfer, system lubrication, corrosion prevention, rust prevention and cooling in the hydraulic system. For the buffer oil, the hydraulic device should first meet the requirements of liquid viscosity at the operating temperature and starting temperature, and the viscosity of the oil changes directly with the hydraulic action.

Hydraulic Oil Buffer

2.Spring Buffer: During elevator operation, the spring buffer compresses or extends, absorbing the elevator’s kinetic energy and slowing down its speed, thus reducing the impact force. They typically consist of a buffer, buffer plate, compression spring, and spring plate. However, the use of spring buffers is limited. They can only be used on very low-speed elevators and may not provide a satisfactory ride experience for passengers. However, hydraulic buffers provide a continuous and uniform buffering process without rebound effects, making them suitable for use in low-speed, medium-speed, and high-speed elevators.

What is the material of the elevator buffer spring?

Elevator buffer springs must be elastic and durable enough to deform and store energy when stressed. They are usually made of spring steel or high-strength alloys and can withstand long-term use and repeated loads without failure. Therefore, the spring also needs to have a certain corrosion resistance, can cope with humidity, high temperature or chemical corrosion and other environmental effects, to ensure long-term stable operation.

Spring Buffer

3.Polyurethane Buffer: Lightweight, easy to install, maintenance-free, provides excellent buffering effects, high impact resistance, good compressive performance. During the buffering process, it is noiseless, spark-free, and has excellent explosion-proof properties, ensuring safety, reliability, and stability. Polyurethane has excellent energy absorption capacity and elasticity. It can quickly return to its original state when the elevator stops, releasing stored elastic potential energy, thereby reducing impact force. Polyurethane buffers are typically used for elevators with speeds less than or equal to 1 meter per second.

Polyurethane Buffer

How to test the elevator buffer for damage?

The test of the elevator buffer usually includes checking the appearance and structure, paying special attention to the integrity of the spring, hydraulic buffer and other components, performing functional tests to simulate the role of the buffer in the case of the elevator stop or emergency stop, performing pressure tests to ensure that it can withstand the rated load, checking and maintaining the lubrication system to ensure smooth operation. Finally, record the test data and report any anomalies or problems that need to be fixed. These tests should be carried out by professionally trained maintenance personnel or technicians. During the tests, everything shoulde be strictly in accordance with relevant safety codes and standards to ensure the safe operation of the elevator.

These are common types of elevator buffers, each with slight variations in design and operating principles, but all aimed at providing safety protection and passenger comfort during emergency stops. The choice of which type of elevator buffer to use typically depends on the elevator’s design requirements, operating environment, and performance needs.

Why choose us?

China’s leading elevator&escalator parts supplier, A-FLY International Limited, has been specializing in escalator parts for over 20 years. We pride ourselves on providing top-quality products, stable supply, reasonable prices, prompt delivery, and professional service. If you have the requirements for elevator buffers, please feel free to contact us through phone or email. We are looking forward to your message.