What Are the Common Specifications of Escalator Friction Wheels?

In an escalator system, the friction wheel is one of the most essential components for ensuring smooth and safe operation.By working together with the drive chain, step system, and braking mechanism, it performs several critical functions — including power transmission, positioning, and anti-slip control.Though small in size, the friction wheel directly affects the efficiency, stability, and comfort of an escalator’s operation.

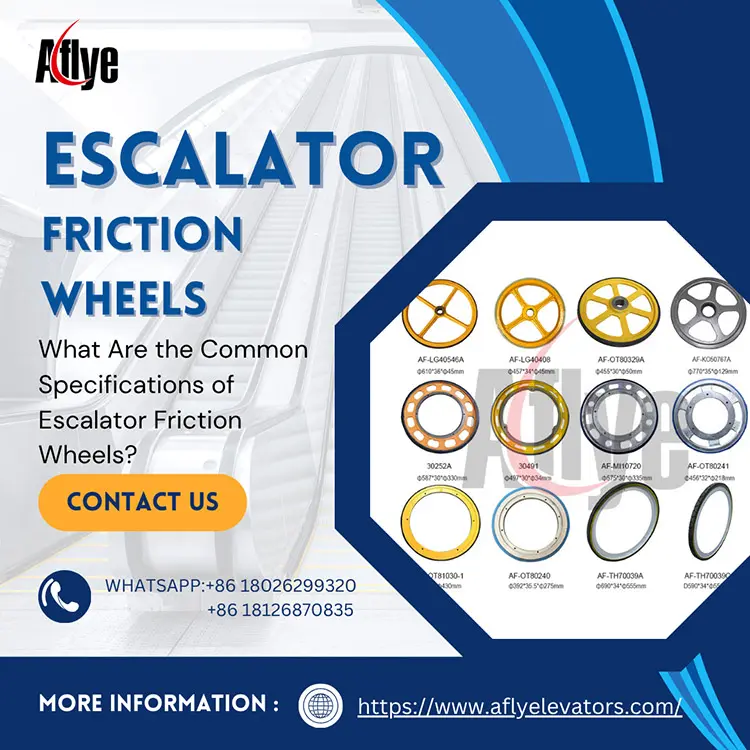

Today, the technical team from A-FLY Elevator & Escalator Parts Supplier will explain the main functions and common specifications of escalator friction wheels.

1. Main Functions of Escalator Friction Wheels

Friction wheels are usually installed in the drive unit, step chain, or handrail system.

Through surface friction, they achieve power transmission and synchronized operation.

Key functions include:

Power Transmission

The friction wheel engages with chains, belts, or rollers to transfer torque and motion — it is a key driving element in the escalator’s operation.

Stable Operation

Made with high-precision rubber or polyurethane coatings, it absorbs vibration and reduces noise, ensuring smoother and quieter movement.

Anti-Slip Protection

The wheel surface often features grooves or anti-slip coatings, maintaining stable traction even in humid or high-load environments.

Extended Equipment Lifespan

High-quality friction wheels minimize direct metal-to-metal wear between chains and rollers, helping to prolong the entire system’s service life.

2. Common Specifications of Escalator Friction Wheels

Depending on installation position and structure, friction wheels come in various sizes and specifications.

A-FLY provides a full range of models, typically categorized as follows:

Φ60mm – Φ100mm Small Friction Wheels

Used in handrail or chain guide areas, featuring compact structure and lightweight design.

Examples: D55, D60 guiding wheels.

Φ120mm – Φ180mm Medium Friction Wheels

Commonly used in handrail pressure wheel assemblies, such as J TYPE or EX TYPE models (D132, D141).

Φ400mm – Φ700mm Large Friction Wheels

Designed for main drive or braking systems, providing higher wear resistance and stability.

Examples: D587 friction wheel for OTIS 9300, D457 for SCE systems.

Different models can be customized according to outer diameter, inner hole size, groove shape, and rubber thickness to match brand and design requirements.

A-FLY’s Friction Wheel Series offers combinations of nylon, polyurethane (PU), rubber-coated, aluminum-core, and steel-core structures.

3. Material Selection for Escalator Friction Wheels

The performance of a friction wheel depends not only on size accuracy but also on material quality.

Common materials include:

Polyurethane (PU): Wear-resistant, aging-resistant, and highly elastic — ideal for frequent-use escalators.

Rubber: Excellent vibration absorption and noise reduction — suitable for commercial environments.

Nylon: Lightweight and durable, with moderate friction — used for medium-speed escalators.

Aluminum or Steel Core: Provides high load capacity and stability, extending the wheel’s overall lifespan.

A-FLY strictly controls material composition and temperature during production to ensure every friction wheel has superior wear resistance, balance, and low-noise performance.

4. A-FLY — Your Reliable Escalator Parts Supplier

As a professional elevator & escalator parts supplier, A-FLY has years of industry experience specializing in R&D and manufacturing of key escalator and elevator components.

Main Products Include:

Escalator Drive and Guide Wheels

Elevator Traction Sheaves and Compensation Wheels

Elevator Buttons, Displays, and Door System Parts

All A-FLY products undergo dynamic balance testing and wear-resistance verification, supporting OEM/ODM customization and global shipping.They are widely used in escalator maintenance, modernization, and complete system projects.

5. Conclusion: Stability in Friction, Safety in Motion

Though small, the escalator friction wheel plays a vital role in ensuring safe and smooth operation.Choosing the right specifications and high-quality materials helps reduce maintenance costs and enhance passenger comfort.Choose A-FLY — for smoother operation and more reliable escalator performance.A-FLY — The Professional Elevator & Escalator Parts Supplier, delivering high-performance friction wheel solutions worldwide.